Building

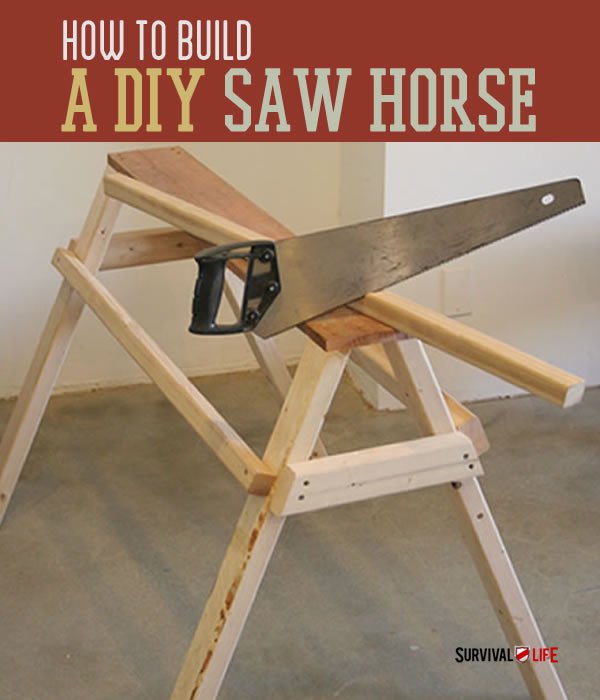

How To Build A DIY Saw Horse

Learning how to make a sawhorse is a very basic woodworking project.

And knowing some basic woodworking could be a big help to you when the SHTF.

Not only will building this sawhorse give you a new tool to aid in your self reliance, but it will work as a great jumping off point for learning a new craft.

This sawhorse can be made with all manner of wood and be any number of different sizes.

The nice thing about making your own sawhorses is you can build them exactly the size you need, so you can make big ones to hold a table, small ones for cutting stands, giant ones for crowd control, etc.

Read on and get to building!

Materials

- (6) 1×3 lumber at 3 feet in length (you can go bigger or smaller, longer or shorter)

- (1) 3/4 inch x 5-1/2 inch plank or board at 3 feet in length. This board could be any length, but keep in mind that it will be your work surface and should be long enough to give you a comfortable amount of space to work on.

- (2) 1×3 lumber at 1 foot in length

- (1) Drill

- (1) 1/8 inch Drill Bit

- (1)Phillips Head Bit

- (1) Miter Saw

- (2) Wood Clamps

- (24) 2-1/2 inch Wood Screws

- (1) Pencil

- (1) Measuring tape

*Remember, these board sizes and lengths can easily be changed to make a different sawhorse. These dimensions are just so you can follow along with exactly what we built.

Step 1: Make the legs

Cut four pieces of wood so that they are three feet long. We used 1×3 wood, but you could just as easily use a different sized wood throughout. If you DO use different sized wood, however, be sure and also use that same size wherever we mention 1×3 pieces in this tutorial.

You can use a regular ‘ol handsaw for this as well.

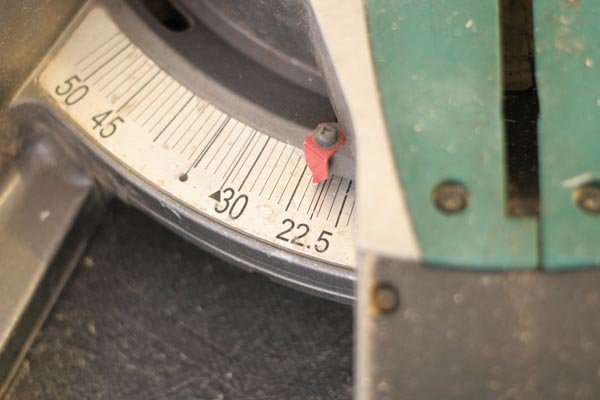

Step 2: Prepare your saw for angled cuts

All miter saws are different, but all follow pretty similar principles. To make angled cuts with a miter, loosen the rubber handle at the front by twisting it counterclockwise.

With your thumb, press down on the lever that is above the handle.

This may not look exactly the same as yours, but it will likely be quite similar.

Rotate the cutting board to 22.5 degrees. We are cutting our boards at 22.5 degrees so they will lay flush against the sides of our sawhorse when it is ready and angle out away from the horse to provide a steady base. Don’t worry if this doesn’t make sense yet, we have a degree in Wood Math from Beaver University…not really.

Step 3: Clamp your legs for easy cutting

After you have cut your four leg pieces, clamp them together with some wood clamps. We are doing this so we can cut all of our legs at once.

Step 4: Make your first angled cut

Make the first 22.5 degree cut to either side of your clamped, 4-board system. It does not mater which side so long as the boards are laying on slim-side as shown. Cut as close to the edge as you can while still getting a full angled cut.

Be sure to practice safety when using power tools.

Step 5: Make your second cut

Cut the other end of the legs as well. Angle the cuts on the other side so that the sides run parallel to each other. Same as the first angled cuts, cut as close to the ends as possible. The end result will look like this:

Step 6: Get your top piece

Grab a board for the top of the sawhorse. We made our top board 3 feet long, which means that our sawhorse will be three feet long. In other words, this will give us three feet of space to saw things on. Your board could be longer or shorter – just pick a length that will give you ample room to work comfortably.

We found this old board lying around the shop.

Step 7: Get those legs on

Attach the legs to the top board with screws. Begin every hole with a drill bit slightly smaller than your screw so that the wood does not split when the screw is fastened. We’re using a 1/8 inch drill bit.

Fasten the leg to the board with a screw. We used 2-1/2 inch wood screws, but any length will work so long as the screw can pass through the board and at least one inch into the leg. Hold the leg flush against bottom of your top board when drilling. The top of the leg should fit perfect under the board while the bottom of the leg should angle out and fit perfectly on the flat floor.

Repeat this so that each leg has two screws attaching it to the board.

Step 8: Do this for every leg

Repeat this for every leg, creating two A shapes on either end of your top board as shown.

Your sawhorse is almost there, but it is a little wobbly. Better add some support braces!

Step 9: Make short support braces.

Clamp two 1×3’s on top of each other and make 22.5 degree angle cuts at each end.

Flip those two pieces over and cut the other ends as well so that the cuts angle towards each other like you see below. Make these boards roughly 1-foot long…

For the rest of the instructions from DIY Projects, click here.

Want more DIY Projects? Check out these posts:

DIY Home Security For Preppers

Like this post?

Be sure to like us on Facebook so you can be the first to know about latest survival tips and off the grid living skills.

-

Do It Yourself7 months ago

Do It Yourself7 months agoParacord Projects | 36 Cool Paracord Ideas For Your Paracord Survival Projects

-

Do It Yourself9 months ago

Do It Yourself9 months agoHow To Make Paracord Survival Bracelets | DIY Survival Prepping

-

Do It Yourself9 months ago

Do It Yourself9 months ago21 Home Remedies For Toothache Pain Relief

-

Do It Yourself10 months ago

Do It Yourself10 months agoSurvival DIY: How To Melt Aluminum Cans For Casting

-

Exports8 months ago

Exports8 months agoAre Switchblades Legal? Knife Laws By State

Pingback: DIY Rainwater Collection System | Survival Life - Survival Life | Preppers | Survival Gear | Blog

Pingback: DIY Rainwater Collection System | Pioneer Settler | Homesteading | Self Reliance | Recipes

Pingback: How to Make a Rainwater Collection System | Survival Life

Dave in Fairfax

June 25, 2019 at 11:05 AM

The legs need to be cut at a compound angle so that they slope not just towards the mid-line of the top board, but also slightly inwards, front to back, so that the saw horse doesn’t rack when used. If you replace the end cross pieces with a piece of plywood that butts up to the top board it will be much stronger.

Pingback: Joining Wood with Dowels | 10 Easy Steps to Join Wood with Dowels – The Self-Sufficient Life

Pingback: Joining Wood with Dowels | 10 Easy Steps to Join Wood with Dowels – Bulletproof Survivors

Pingback: Joining Wood with Dowels | 10 Easy Steps to Join Wood with Dowels – Sprent Brass